SKF, recognised globally as a market leader in sustainable rotating products and technologies, continues to shape the future of industrial performance, setting new benchmarks through innovative, eco-conscious approaches, with circularity woven into the core of its design, manufacturing and lifecycle strategies.

“These strategies are anchored in our new company purpose – together, we reimagine rotation for a better tomorrow – whichis already deeply embedded in SKF’s DNA, underpinning every decision and change we make, from product design and manufacturing to the solutions and services we deliver to industry,” asserts Micaela Willers, Manager for power transmission and training at SKF South Africa.

Highlighting the pivotal role of product design and development, Willers points to the new SKF Infinium bearing as a prime example of the company’s drive to advance circular design principles. As the name implies, SKF Infinium bearings can essentially be remanufactured an indefinite number of times. Engineered with advanced cladding technology and utilising cutting-edge Laser Metal Deposition (LMD), these new bearings can be repeatedly recladded and reused without compromising their quality or performance, marking a significant breakthrough in circularity and additive manufacturing.

“We have not yet set a timeline for introducing this advanced level of remanufacturing locally; however, we already provide a well-established manufacturing service for larger bearings which boasts a strong track record in South Africa,” shares Willers. She also reveals that SKF South Africa is currently laying the groundwork for establishing a dedicated bearing remanufacturing centre to support Africa’s railway industry.

The recently introduced SKF Infinium bearing innovation forms part of a broader set of forward-looking initiatives aimed at improving circularity, reducing carbon footprints and enhancing the lifespan and cost-effectiveness of SKF’s bearing and power transmission product ranges.

“By fostering circularity, we strive to transform how people perceive bearings,” explains Willers. “Instead of viewing them as disposable consumables to be discarded once ‘spent,’ we want bearings to be recognised as valuable assets that should be nurtured, serviced and returned to service through remanufacturing when performance begins to decline.” Willers notes that the consumable or throwaway approach not only increases costs over a machine’s lifetime but also carries significant risk. “Opting for lower-quality components to cut expenses can lead to major equipment failures and costly repairs,” she warns.

“That’s why we encourage our customers to adopt a circular mindset. Bearings can be remanufactured by SKF to OEM condition and put back into service.” Willers adds that when bearings are seen as assets to be actively managed, plant operators are more likely to engage with SKF’s expert services which are essential tools in reducing total cost of ownership and extending operational life. “This is unquestionably the most sustainable and cost-effective path forward.”

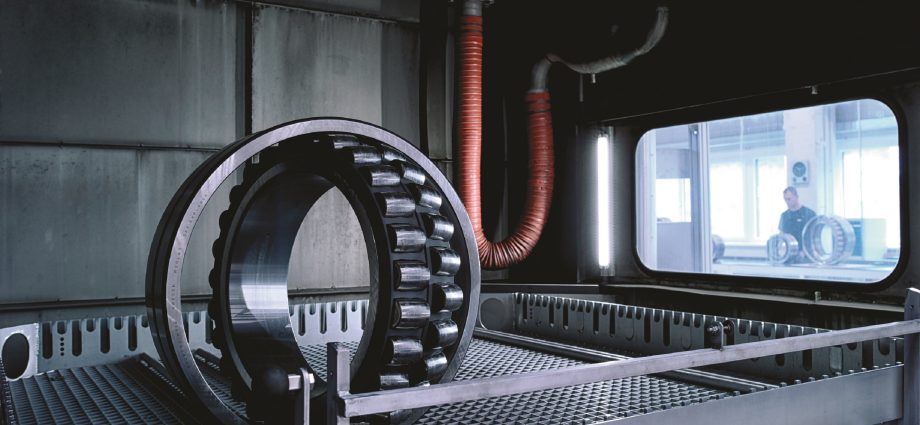

Moving on to the fundamental topic of emissions, Willers notes that globally, SKF is aiming to achieve a fully carbon-neutral manufacturing footprint by 2030 and net-zero emissions across its entire supply chain by 2050. To support this eco-ambition, the company is engaging in several initiatives with leading steel producers to actively reduce production-related emissions. This includes the use of hydrogen direct reduced iron (H-DRI). Thanks to this revolutionary technology that decarbonises the steel used in its bearing production, SKF, in collaboration with Nordic steel producer, Ovako, is now able to produce spherical roller bearing (SRB) with 90% less embedded carbon compared to standard SRB bearings. “We use a high quality bearing steel produced from 97% recycled steel and leverage advanced manufacturing capabilities within SKF’s net zero factory in Gothenburg, Sweden,” notes Willers.

Developing premium quality bearings and cutting-edge technologies, harnessing over a century of experience and providing specialist services are all deeply rooted in SKF’s history. The organisation is steadfastly committed to empowering customers by reducing the total cost of ownership of its bearings. “We subsequently take a full lifecycle approach to every installation; selecting the right bearing and ensuring proper installation for our customers are critical as any errors can significantly reduce the bearing’s operational life,” asserts Willers.

In a bid to extend bearing lifecycles and ultimately optimise customers’ rotational assets, SKF supports its products and technologies with the timely delivery of mechanical field services, engineering support, condition monitoring, lubrication systems, and remanufacturing solutions. “The implementation of effective lubrication systems and management for example will ensure that each bearing receives the correct type and amount of lubricant at the right time,” explains Willers. “To monitor the health of both the bearing and the machine, we offer advanced condition monitoring systems. Once a defect is detected, using AI technology, we are able to determine both the root cause and the remaining useful life, enabling a safe, scheduled removal, remanufacture and reassembly process.”

Willers points out that this holistic approach also extends to enhancing the performance and efficiency of transmission systems in existing equipment. “Whether it’s a retrofit belt drive solution for a slurry pump or a chain drive for a conveyor in the pulp and paper industry, we take a holistic view of the entire drivetrain, including pulleys, gearboxes, motors and bearings. This strategy will ensure that every element of the rotating system, from correct product selection to power ratings, speeds and torques, will contribute to long-term reliability and reduced total cost of ownership. By switching to modern materials and component designs, applying due diligence and ensuring fit-for-purpose sizing of every component, we optimise the complete system to improve operational efficiency and unlock significant cost savings.”

“Through the design and manufacture of components with sustainability at their core, we, in partnership with our customers, are driving a better, more sustainable tomorrow. By mobilising our full suite of product and technology innovations, we are reimagining the future of rotation, rolling away from traditional, consumable-based thinking toward a smarter, more sustainable circular approach.”

/Ends/