In a strategic effort to optimize resource recovery, a South African gold mining operation successfully deployed Grindex Bravo 500 slurry pumps from Integrated Pump Technology to reprocess slurry from its surface return water dam. This dam, which had served as a process water storage facility for the past 12 years, was identified as a valuable source of gold-bearing slurry. The objective was to transfer this slurry back to the gold processing plant, with the Grindex Bravo 500 pumps selected as the most suitable solution.

The return water dam played a critical role in sustaining gold production during a period of underground maintenance that temporarily halted recovery from a specific section. The dense slurry, with a specific gravity (SG) of 1.38, presented a significant challenge for pumping. However, the material’s density was similar to the slurry already processed by the plant’s thickeners, meaning no modifications to the existing process plant were necessary. Instead, the focus was on ensuring the pumps could reliably handle the application’s parameters.

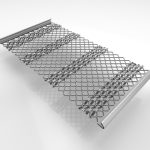

Following a detailed assessment of the site conditions, the Grindex Bravo 500 was chosen for its ability to withstand the density of the slurry while transferring it at the required flow rate. Designed for heavy-duty applications, the pump’s components, such as the impeller and liner, are built to endure the abrasive nature of dense slurries.

A key factor contributing to the success of the operation was the high flow rate and reliability of the Grindex Bravo 500 pumps. In this application, the pumps were transferring material at a flow rate of 480 m³/h with a head of 18 meters. A total of three Grindex Bravo 500 pumps were deployed, showcasing their capacity to handle the demanding requirements of this gold mining reprocessing project.

The Grindex Bravo 500 is engineered to manage high head pressures, an essential feature when transporting dense slurries over long distances or vertical lifts. Its ability to maintain consistent pressure ensures the smooth movement of heavy slurries through the system. Additionally, the pump’s robust impeller design efficiently handles the high-density slurry, reducing the risk of blockages and ensuring continuous operation.

The overall construction of the Grindex Bravo 500, which includes heavy-duty bearings and a durable shaft, is designed to withstand the stresses of pumping dense materials. Furthermore, the design minimizes the risk of cavitation, a common issue when dealing with high-density slurries.

In a related application, a Grindex Bravo 500 was also deployed to pump clean water from the return water dam to the plant, where it was used to wash material back into the system.

This deployment highlights the effectiveness and robustness of the Grindex Bravo 500 in managing high-density slurries in mining operations, enabling the reprocessing of valuable materials while ensuring operational efficiency and reliability.