Across the mining industry, a notable trend has emerged where original equipment manufacturers (OEMs), engineering, procurement and construction management (EPCM) contractors and mine operators are increasingly calling on Weba Chute Systems to assist in resolving process flow issues that impact plant performance. These challenges typically arise when new or existing screens, crushers or feeders underperform due to inefficient material transfer between stages in the processing circuit.

Transfer points – often the hidden bottleneck

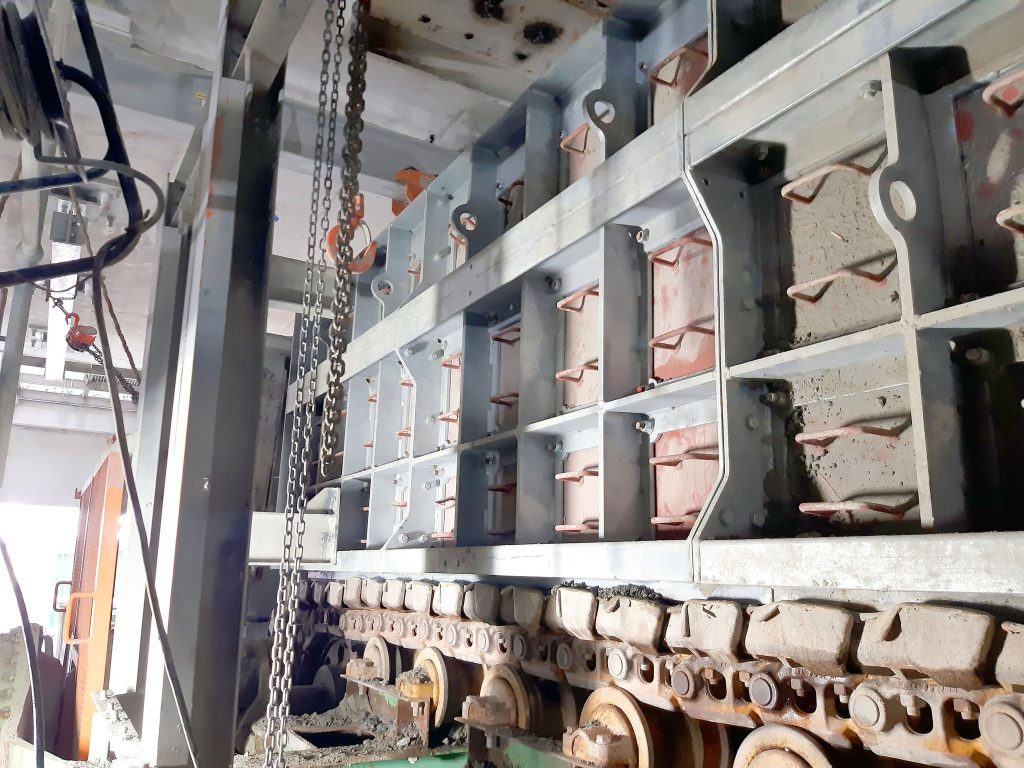

While new equipment installations are generally well specified, the transfer chutes linking different units of process equipment are frequently overlooked. These transfer points can become the source of major bottlenecks, leading to issues such as uncontrolled material velocity, excessive impact, spillage, uneven feed distribution or accelerated wear. The result is often premature failure of liners or vibrating equipment, increased downtime and overall loss of plant efficiency.

According to Mark Baller, Managing Director of Weba Chute Systems, the company is often called in once other avenues have been explored and the source of the problem remains unresolved.

“In many cases, the mine or project team initially focuses on the mechanical or structural performance of the upstream equipment,” Baller explains. “However, when the problem persists closer inspection often reveals that the root cause lies in the uncontrolled manner in which the material is being transferred from one point to another.”

He emphasises that even small deviations in material flow trajectory, velocity or impact angle can have a significant influence on how effectively downstream equipment performs.

Experience and engineering insight

With one of the largest global reference bases of custom-engineered chute systems, Weba Chute Systems has extensive experience across a wide range of commodities – from iron ore, coal and manganese to platinum, gold and copper – and across virtually every part of the process flow sheet.

This depth of experience enables the company’s engineers to quickly identify where transfer conditions are contributing to a problem and to propose targeted solutions based on proven designs and data. Each investigation typically begins with a detailed site assessment and data collection phase, followed by discrete element modelling (DEM) simulation to replicate material behaviour under actual operating conditions.

“Through these simulations,” Baller explains, “our team is able to visualise material trajectories, particle interactions and wear patterns to pinpoint exactly where problems occur – whether this involves excessive material build-up, misalignment or uncontrolled impact. This scientific approach ensures that any redesign is not based on trial and error but on quantifiable evidence.”

Case studies from the field

In one example, an EPCM contractor overseeing a manganese screening plant upgrade approached Weba Chute Systems after newly installed screens began suffering frequent pegging and uneven feed distribution. DEM analysis revealed that the existing transfer chute design was creating a concentrated material stream, overloading one side of the screen and causing vibration imbalances.

Baller says that by redesigning the chute with an optimised internal geometry to control the flow trajectory and distribute the feed evenly, the Weba Chute Systems team eliminated the pegging problem and restored screen performance. The result was more stable operation, improved product grading and reduced maintenance costs.

In another instance, a platinum concentrator experienced repeated blockages and severe liner wear in a transfer point feeding its secondary mill. Although the mill itself was mechanically sound, DEM simulation confirmed that material was entering the mill feed chute at excessive velocity, leading to impact wear and uneven distribution. Weba Chute Systems designed a replacement chute incorporating energy absorption and flow control features, resulting in over a threefold increase in liner life and a significant reduction in unplanned downtime.

Systemic improvement, not isolated fixes

Baller notes that the company’s approach is always holistic. “We seldom treat a transfer point as an isolated component,” he says. “Each chute interacts with the process upstream and downstream. Our objective is to stabilise the entire system – ensuring that equipment such as screens, feeders and mills are protected and operate within their design parameters.”

This systems-based philosophy has proven particularly valuable to EPCM teams, who are often tasked with ensuring plant performance guarantees. By engaging Weba Chute Systems early in the design or optimisation process, they can reduce commissioning risks, achieve smoother start-ups and deliver plants that perform reliably from day one.

Reliable solutions across the flow sheet

From primary crushing and screening to secondary milling, flotation and concentrate handling, Weba Chute Systems’ designs are engineered for each application. The company’s solutions have become industry benchmarks for controlled material flow, reduced dust generation, improved wear life and higher availability.

“Every mine is under pressure to maximise throughput and minimise downtime and our role is to ensure that material transfer – a seemingly minor aspect of the plant – does not become the limiting factor in achieving those goals,” Baller concludes.