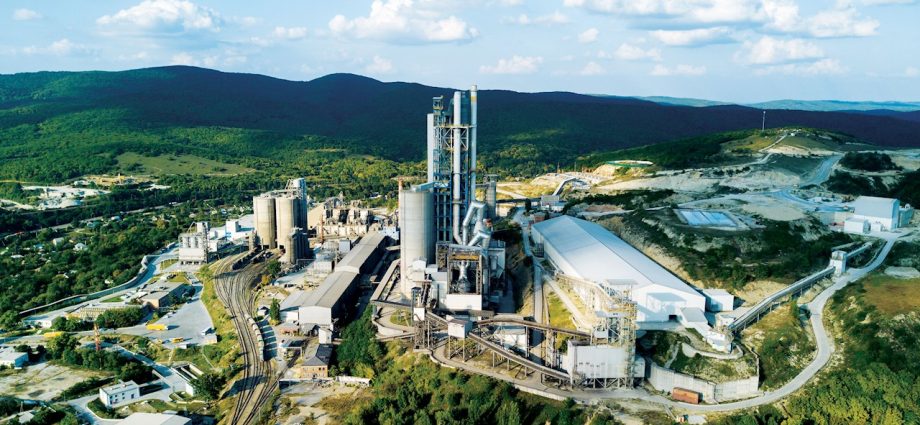

Cement is essential in modern construction but comes at an environmental cost, with its production being energy-intensive and reliant on fossil fuels. Currently responsible for approximately 7% of global carbon emissions, cement production is projected to emit 3.8 billion tons of CO₂ by 2050 if no action is taken. The industry, therefore, faces a pressing need to balance productivity with sustainable practices.

ABB’s latest white paper offers a roadmap for a sustainable cement future, combining insights from industry leaders—including customers, technology partners, media, and associations—with ABB’s expertise in process solutions. The publication details how advanced electrification technologies, developed in collaboration with engineering specialists like Coolbrook and their RotoDynamic Heater, are poised to reduce emissions and transform cement production.

The white paper explores what sustainable cement production could look like and provides actionable steps that producers can adopt today. Electrification is a focal point, with solutions that aim to replace fossil-fuel burners with zero-carbon alternatives. This approach has the potential to dramatically reduce emissions in line with the industry’s decarbonization targets.

A significant portion of the cement industry’s emissions arises from the calcination process, which consumes large amounts of energy to achieve the high temperatures required for chemical transformation. ABB’s publication details electrification pathways to decarbonize this process. Collaborations with partners like SaltX demonstrate viable electrified solutions, utilizing renewable electricity and incorporating carbon capture. Additionally, ABB’s partnership with Captimise is geared toward conducting feasibility studies and engineering designs to support cement producers in implementing effective carbon capture systems.

Bodil Recke, ABB’s Global Manager for Business Unit Cement, emphasizes the importance of cross-industry collaboration in driving decarbonization. “No single player can address all aspects of cement production decarbonization alone, which is why sharing insights across industries, as presented in this white paper, is crucial to advancing a sustainable future,” she states. The publication highlights solutions to improve sustainability, enhance performance, and reduce energy costs through a cycle of monitoring, forecasting, and optimizing energy consumption.

ABB’s commitment extends further through its Real Progress initiative, aiming to help customers avoid 600 megatons of CO₂ emissions from 2022 to 2030. This initiative emphasizes a comprehensive approach to reducing material use, decreasing reliance on fossil fuels, minimizing waste, enabling circular processes, and prolonging asset life across the cement industry’s value chain.