When engineering, procurement and construction (EPC) firms plan new mining projects or expansions, the cost of mine development, system installation and operating the materials handling system is front-of-mind – and this is where hybrid technologies like Railveyor attract growing interest.

Moving material on mining and other industrial applications can be a leading cost-driver for EPC contractors to consider, especially where long distances must be covered, or where there are challenging grades or terrain and tight curves to be navigated. In these conditions, the materials handling aspects of development can become a critical cost that affects the very viability of a project. Adding to this, the growing focus on sustainability and carbon emissions, prompting both EPCs and their clients to seek innovations that meet multiple objectives simultaneously.

In this space, hybrid systems have gained prominence by combining the strengths of proven technologies while effectively overcoming their limitations. The Railveyor system builds on the advantages of light rail and conveyor technology, while improving levels of automation and safety. The robust concept allows for optimal design flexibility, delivering strong reliability for more productive and streamlined operations.

What is so different?

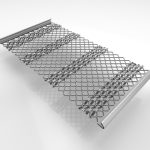

The system is based on individual steel rail cars that make up a train, connected to each other with steel clevis assemblies and flexible flaps that prevent material spillage. Rather than using a locomotive, the train is driven by automated drive stations – each comprising two horizontally oriented wheels powered by electric motors. These propel the train through contact with the side plates on each car.

The train runs on tracks that can be installed on a lightly ballasted substrate, thereby avoiding the cost and fixed nature of the concrete foundations required by conveyors. The lightweight infrastructure can be relocated by a small crew in a matter of hours, making it very flexible in response to changing mining plans and expansions. Loading of the cars can be done in several ways, including a simple overhead hopper or chute, a pan feeder or a discharge conveyor.

Overcome demanding specs

Railveyor’s versatility allows it to match the technical specifications of any new project or expansion, integrating readily into the project plan. At the heart of the system’s efficiencies are the lightweight cars running on steel tracks – for the lowest rolling resistance – and delivering a high payload-to-weight ratio.

Where an EPC is designing a mining operation in complex terrain or with steep gradients, the Railveyor stands out as a game-changing solution. For example, while traditional conveyors typically need a turning radius of at least 500 metres, where the Railveyor can navigate turns as tight as 30 metres – or even 20 metres when using smaller cars. On steep slopes, conveyors are prone to material roll-back, often requiring extensive grading or rerouting during installation. In contrast, the Railveyor system handles gradients of up to 30%, enabling more direct, cost-effective routing and reducing the need for costly infrastructure modifications.

Power of digital control

Digital technology significantly boosts the system’s efficiency and safety, with the company’s proprietary TrulyAutonomous™ system enabling full automation through advanced software. This allows daily operations to run without human intervention or the need for personnel to be nearby – streamlining material handling, increasing production and placing safety at the forefront. Loading, haulage and discharge functions – customised to align with the mine’s infrastructure and production needs – can all be fully automated.

The TrulyAutonomous™ software communicates with variable frequency drives (VFDs) to control the 75kW motors in the drive stations with precision timing. Speeds, torques, currents and other variables related to the operation of the train can be centrally controlled and monitored. To further enhance power efficiency, the driven stations can even regenerate energy when the train moves on a decline.

More conducive workplace

Energy efficiency not only lowers operating costs and carbon emissions, but the Railveyor’s quiet operation also reduces noise, creating a more conducive and comfortable work environment. Powered by electric technology, the system eliminates diesel fumes in underground operations, significantly reducing ventilation requirements. These advantage help align with the standard operating procedures and environmental benchmarks set by EPCs for their mines.

Finally, Railveyor’s proven performance in the field has earned the company strong references – most notably its installation at Agnico Eagle Mines’ Goldex complex in Canada, where operating costs were reduced by 75% and carbon emissions cut by 39%.