Liebherr-Werk Bischofshofen GmbH, along with ZF Friedrichshafen AG, reached an exciting milestone: the 10,000th XPower wheel loader with power-split transmission from ZF has officially rolled off the production line. To mark the milestone, representatives from ZF’s Passau site travelled to Bischofshofen to celebrate the successful partnership. Representatives of the BERGER Group, who took delivery of their machine in person, and representatives of the Beutlhauser Group, who sold the XPower wheel loader to the buyer, were also present at the anniversary event.

Liebherr-Werk Bischofshofen GmbH is a long-standing development partner of driveline specialist ZF. Drawing on its decades of experience in developing wheel loaders, Liebherr actively contributed to the development of the power-split transmission so that the manufacturer could optimize it for the requirements of the XPower travel drive.

Celebrating the 10,000th wheel loader

The milestone wheel loader with special decals and a hand-signed transmission by ZF employees is going to the BERGER Group in Passau, where it will be put into service near the ZF transmission plant in a BERGER Rohstoffe GmbH quarry in the Bavarian Forest. Matthias Neidhardt, managing director of BERGER Rohstoffe GmbH, Johannes Urmann, authorized signatory, and Michael Gruber, technical division manager, travelled to Bischofshofen to receive their new wheel loader at the handover ceremony.

During the ceremony, Dr. Herbert Pfab, managing director of technology at the Liebherr plant in Bischofshofen, presented the new owners with a symbolic key for the new XPower. The BERGER Group has 20 XPower wheel loaders in operation and is delighted with the special machine.

Features on the XPower wheel loaders

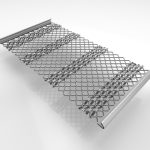

For almost a decade, the L 550 to L 586 XPower wheel loaders have been successfully used across industries. The power-split drive system combines both hydrostatic and mechanical drives. The hydrostatic travel drive is the most efficient drive type for short loading operations, while the mechanical drive is the most powerful and economical for long distances and uphill driving.

The power-split ZF transmission is responsible for combining the two drive paths. It operates variably and adjusts the mixing ratio of the two drive paths continuously and automatically. The wheel loader always operates at maximum power and efficiency, regardless of the application. With the expertise of its development partner ZF, Liebherr can integrate the transmission into the entire drive system and match all components precisely to each other.

“The transmission from our partner ZF is a key component of the drivetrain in our XPower wheel loaders. With an impressive total of around 64,000,000 operating hours already clocked up by XPower models, this transmission has proven its exceptional robustness,” explains Gerhard Pirnbacher, head of quality management at the Liebherr plant in Bischofshofen.