SEEPEX has introduced BN pumps with Smart Joint Access (SJA), engineered for the reliable and precise transfer of abrasive, corrosive, and chemical media in mining and construction. Designed for rock blasting, the pump features a large inspection opening for quick joint checks, a compact footprint for mobile or skid-mounted installations, and flexible drive and material options for consistent performance and uptime.

“Operators can inspect joints quickly and rely on precise pumping of shear-sensitive and abrasive emulsions,” said Magalie Levray, Global Business Development Manager Mining at SEEPEX. “This is particularly critical in rock blasting, where every borehole counts for productivity.”

Industry Context

Rock blasting is essential for extracting hard rock and shaping safe excavation profiles in mining and construction. Accurate and consistent loading of explosive emulsions ensures controlled fragmentation, protects personnel, and maximizes productivity. Even minor deviations in pumping can cause delays or reduce product quality. BN pumps with SJA support routine maintenance and pre-operation checks by allowing fast verification of joint integrity, enabling more efficient operations.

Always Inspection Ready

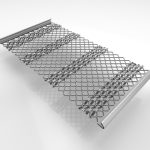

Smart Joint Access is designed for inspection-friendly operations. The large inspection opening in the suction housing provides direct access to both joints, enabling rapid pre-operation checks while maintaining high operational reliability. Technicians can assess joint condition quickly, supporting continuous, reliable operation.

Key Features

- Compact Footprint: Fits truck-mounted mobile units, skid-mounted systems, and factory installations.

- Flexible Drive Options: Compact hydraulic drive or electric drive configurations.

- Hydraulic Efficiency: Low-displacement design reduces oil requirements and supports low total cost of ownership.

- Equal Wall Stator Design: Ensures high-pressure performance in a compact footprint.

- Material Flexibility: Stainless steel or steel housings, chrome-plated rotors, and stators in NBR, EPDM, or FKM.

Operators benefit from shorter inspection cycles, reliable dosing, seamless integration, and fast delivery through framework agreements, helping to maintain uptime in critical rock blasting processes.

Applications – Optimized for Rock Blasting

BN pumps with SJA are designed for mining, tunneling, quarrying, civil works, dam construction, and other sectors requiring precise handling of abrasive or chemical media. They provide robust performance while enabling fast, reliable inspection and maintenance.

With SJA, operators can quickly access both joints without disassembly, ensuring emulsions are transferred accurately and consistently. This reduces downtime, preserves product integrity, and supports uniform dosing across multiple bore holes.

With the Smart Joint Access inspection opening, operators can quickly access and assess the condition of both joints without disassembly, enabling immediate verification of pump readiness prior to blast hole loading. This allows operators to confirm that emulsions are transferred accurately and consistently, protecting personnel, minimizing product degradation, and maintaining uniform dosing across multiple bore holes.

The combination of equal wall stator design, compact integration, flexible drives, and progressive cavity pump technology ensures continuous, reliable operation even in space-limited, high-pressure environments.

Operational Gains in African Deep Underground Mining

Deep underground mining in Africa is characterized by confined production drifts and long access routes. In this environment, blasting service providers rely on skid-mounted and semi-mobile emulsion pumping systems, making equipment accessibility and serviceability critical to maintaining production schedules.

A leading explosives company operating multiple deep underground sites in Southern Africa integrated SEEPEX pumps with SJA into its underground emulsion loading systems. Before the upgrade, routine inspections were time-consuming and labor-intensive. Pumps often had to be transported to surface workshops, fully drained, and dismounted for joint inspection. Without a dedicated inspection opening, full disassembly was required, and pumps were sometimes replaced on a scheduled basis rather than inspected, leading to unnecessary costs and high spare inventory levels.

SJA changes this by providing direct visual access to both joints without removing the pump. Technicians can assess joint condition quickly during routine checks, reducing downtime and improving asset utilization.

“The inspection opening has completely changed how we maintain our underground pumping systems,” said a maintenance technician. “What used to take hours can now be done quickly underground.”

As a result, the operator reduced the number of standby pumps required for redundancy, lowered inspection-related downtime, and improved overall asset utilization. The compact pump design also fits low-profile underground layouts, maintaining reliable and predictable emulsion loading in space-constrained conditions.

By shortening and simplifying inspection cycles in confined underground environments, SEEPEX pumps with SJA help blasting service providers maintain reliable, predictable operations. The solution supports higher equipment availability in deep underground mines, where every intervention must be carefully