Catalyst Metals’ Plutonic gold mine in North Meekatharra, Western Australia, has made the transformative move from analogue to digital operations in preparations for the future of mining technology thanks to RCT-Powered by Epiroc.

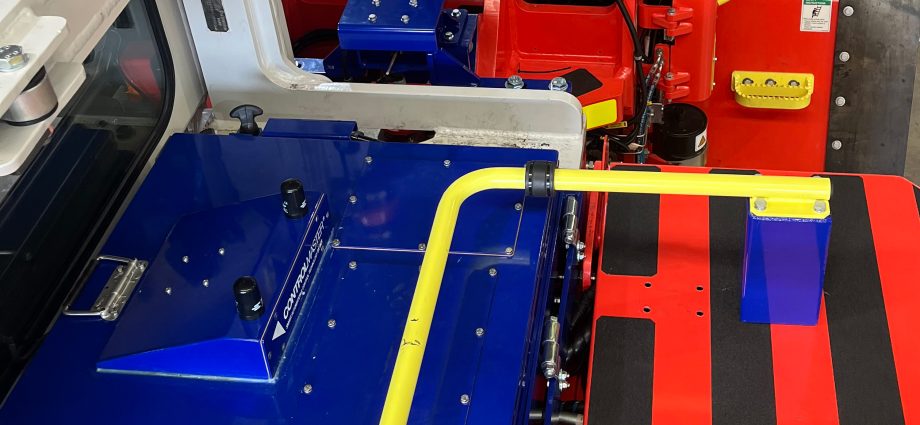

This upgrade is not limited to new equipment but also includes comprehensive upgrades to existing machines, including Sandvik and CAT loaders with the implementation of RCT’s AutoNav package.

This state-of-the-art technology allows the mobile machines to navigate autonomously with higher precision, ensuring increased productivity and a better overall working environment for operators.

A major highlight of this transition is the adoption of modular platforms, allowing operators to control the loaders from inside the comfort of a light vehicle that they can drive to the working stope. With distances between stopes ranging from 3 to 5 kilometres, this provides a flexible and scalable solution for the site which further drives operational efficiency.

In addition, these platforms are designed for easy integration with the newly upgraded digital systems on-site, ensuring seamless communication and data transfer across vast areas of the mine.

To support this digital evolution, the site also upgraded its communication network with RCT Connect, our very own advanced digital Wi-Fi solution.

This upgrade allows operators and maintenance teams to access real-time diagnostics and receive alerts about potential issues before they lead to costly downtime.

Furthermore, the digital systems come with higher tolerance and precision, reducing the likelihood of overheating and other mechanical problems that are often associated with analogue.

Therefore, the result is not just improved performance, but also longer equipment lifespans and lower maintenance costs.

This latest transition from analogue to digital represents a pivotal, forward-thinking approach to modern mining, reinforcing Plutonic’s commitment to innovation and shaping a more sustainable and technologically advanced future.