The recent commissioning of Rino Recycling’s landmark construction and demolition (C&D) waste recycling plant marks a transformative step toward a sustainable future for South East Queensland (SEQ). The cutting-edge plant, located in Brisbane, integrates both wet and dry processing systems and is already making a significant impact by capturing valuable construction materials that would otherwise end up in landfills. This new facility is set to play a crucial role in the SEQ region’s ambitious growth plans, aligning with the goals of the $1.8 billion SEQ City Deal to create a connected, prosperous, and sustainable region.

With South East Queensland expected to see a population increase of over 40% by 2041, this recycling plant is paving the way for a circular economy by offering a viable alternative to virgin quarried materials. Daniel Webber, CDE Australasia’s General Manager, emphasized the importance of the plant as a primary resource recovery line supporting SEQ’s rapid development needs, helping to manage waste responsibly while meeting high environmental standards.

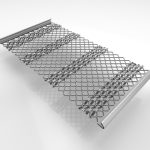

The facility’s hybrid setup allows it to process a wide range of materials, including C&D waste, skip waste, hydro excavation waste, and concrete, through an interconnected system designed for minimal operator intervention. This pioneering integration of CDE’s wet processing with Turmec’s dry systems enables seamless transitions between waste materials, enhancing waste recovery rates in the Brisbane metropolitan area.

Currently operating at 50% capacity, Rino Recycling aims to reach full capacity by 2025, producing high-quality recycled products like fine sand and aggregates that rival traditional materials. The plant’s innovative water management system, featuring CDE’s AquaCycle and HYDROtechnologies, allows it to recycle up to 95% of water on-site, achieving water neutrality—a significant economic and environmental advantage for the region.

With local support from CDE’s new Australian headquarters, Rino Recycling is well-positioned to continue optimizing operations and reducing downtime. This state-of-the-art plant is not only an asset for SEQ’s sustainable development but also a model for responsible resource recovery in fast-growing regions around the world.