The groundbreaking ACS-s condition monitoring system from Sandvik Rock Processing is a transformative solution designed to deliver real-time insights into the performance and operational health of vibrating screens and feeders. Built for the most demanding operational environments, ACS-s empowers mining and processing operations by enabling early fault detection allowing corrective action to be taken swiftly thereby reducing costly unplanned downtime.

“As screens and feeders operate under constant mechanical, traditional maintenance approaches have relied on visual and auditory inspection – often identifying faults only after serious damage has already occurred,” says Frengelina Mabotja, Business Line Manager -Screening Solutions from Sandvik Rock Processing. “Sandvik’s ACS-s changes the game by constantly monitoring the unique vibration patterns of each machine and identifying even the smallest anomalies before they evolve into major failures.”

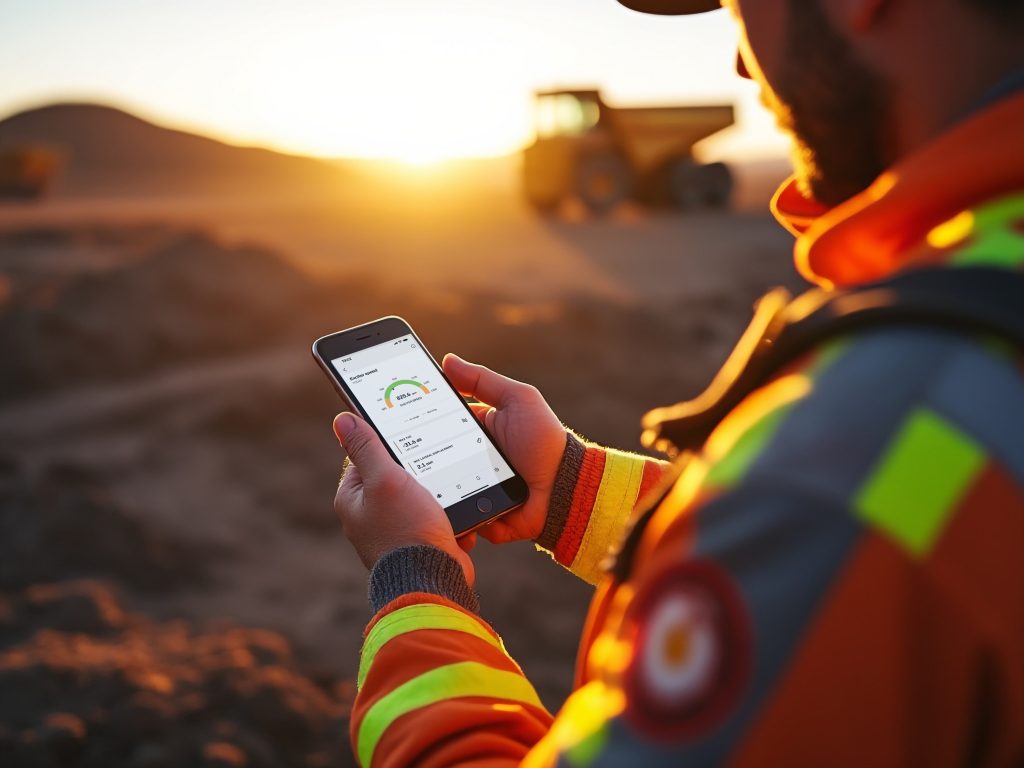

The system’s real-time monitoring capabilities detect the first signs of imbalance, abnormal motion, structural fatigue or unusual acoustic signals. With alerts sent directly to a mobile device or central monitoring dashboard, maintenance teams can intervene early, preventing unplanned stoppages, extensive repairs or production losses. As a result, sites benefit from improved equipment uptime, more reliable performance and lower maintenance costs.

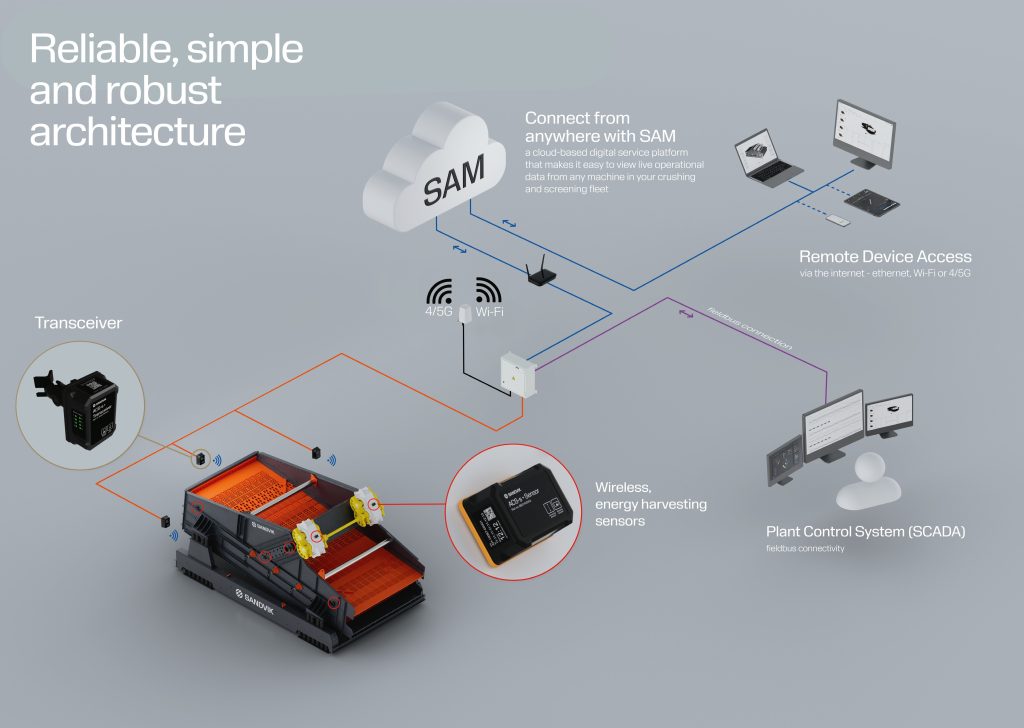

Mabotja says that ACS-s integrates seamlessly with SAM, Sandvik’s cloud-based digital service platform, allowing users to scale up condition monitoring across multiple machines and locations. With up to 32 synchronous sensors per installation and customisable sensitivity for each unit, ACS-s offers unmatched scalability and precision. SAM also enables remote support, where Sandvik engineers can access live data to provide expert advice and troubleshooting.

Designed for easy deployment and maximum flexibility, ACS-s uses magnetically mounted energy-harvesting wireless sensors that require no wired power or data connections. Its built-in router and antenna offer connectivity via LAN, 4G/5G or Wi-Fi, while advanced fieldbus protocols ensure compatibility with plant control systems for seamless integration.

“The ACS-s solution gives operators the choice of in-house monitoring or a collaborative model supported by our global network of service professionals,” Mabotja says. Whether on-site or remote, teams can access real-time diagnostics, interpret fault conditions and follow guided steps to restore optimal equipment functionality.

With its robust architecture, user-friendly design and intelligent software integration, Sandvik Rock Processing’s ACS-s marks a new era in proactive machine health management for screening and feeding applications. “It is an innovation that helps the industry work smarter, moving from reactive to predictive maintenance because early detection is the key to early intervention,” Mabotja concludes.